ENCON Slurry Dryer

The ideal solution for drying liquid solutions and/or sludge

Evaporation is a time-tested & cost-effective method for reducing the volume of water-based waste

Hauling is Costly

Industrial and commercial facilities that generate wastewater spend too much money paying for hauling & disposal of waste streams that are mostly comprised of water.

Evaporation is Cost Effective

ENCON Evaporators are utilized by 2,000+ facilities worldwide to evaporate the water portion of water-based wastes, reducing hauling/disposal volumes and cost by up to or even exceeding 99%.

Advantages of an ENCON Slurry Dryer

- Can handle different waste streams simultaneously

- Can handle very challenging and complex waste streams

- Dramatically reduces disposal volume & cost

- Eliminates sewer discharge accountability

- Achieve ZLD

- Safe to operate 24/7

- Low operating costs

- Requires less operator intervention than most wastewater treatment technologies

- Very effective for process stream concentration

The ideal solution for drying liquid solutions and/or sludge

Achieve Zero Liquid Discharge (ZLD)

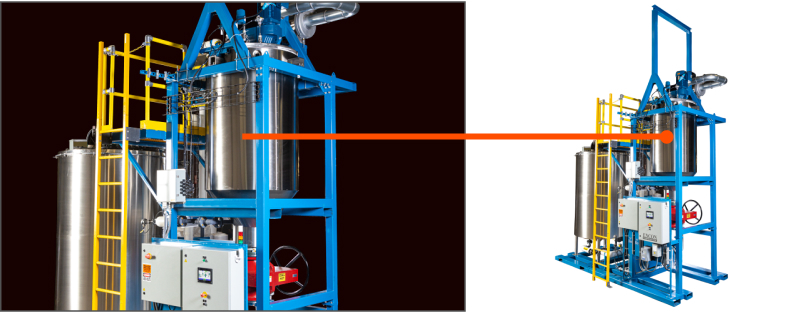

The ENCON Slurry Dryer is engineered to handle liquid solutions in addition to high solids sludges, which makes it an ideal solution for many industrial processes as the solids content of the wastewater generated is often variable. Designed for maximum flexibility, the ENCON Slurry Dryer can operate as an evaporator in addition to a dryer, and can process up to 50 gallons per hour in evaporation mode. Need somethging smaller? Check out the ENCON Drum Evaporator/Dryer.

- Eliminates the need to discharge wastewater

- High-torque, low speed mixing paddle promotes homogeneous drying and prevents moisture cavities

- Can be utilized as a stand-alone single step system for evaporating and drying wastewater or sludge, or implement as the final step in your ZLD process.

Features

Mist Eliminator System

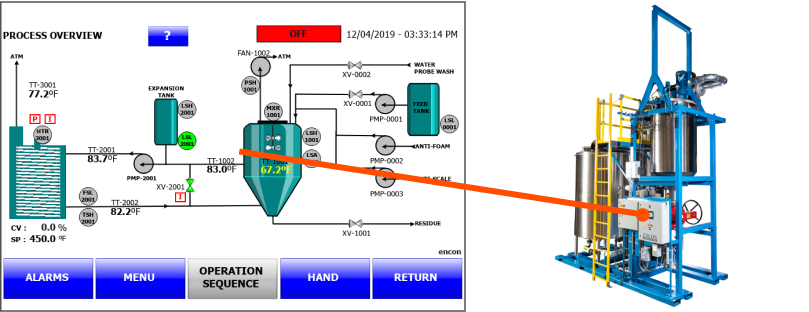

PLC Control Panel

Heavy Duty Mixing Paddle

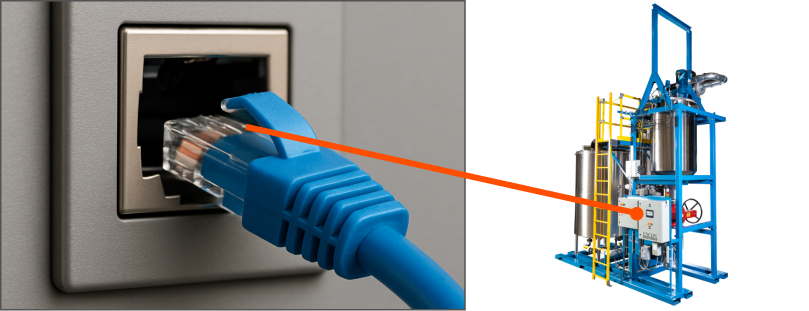

Built-in Ethernet Port

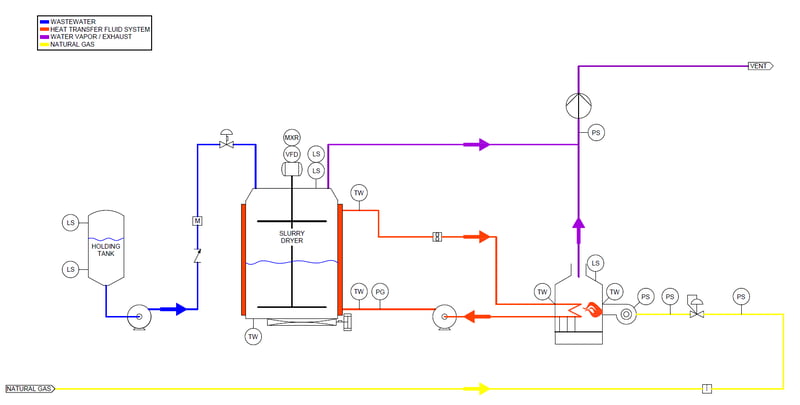

Process Description

- Slurry or sludge is pumped or gravity fed into the Slurry Dryer until the Auto Level Probe is covered.

- Thermal oil begins circulating through the jacket of the dryer vessel and the PLC energizes the thermal oil heater and slurry mixing paddle.

- The slurry is heated to a boil and water is driven off as vapor.

- As the water vapor is driven off, the liquid level will gradually fall below the Auto Level Probe. After a set time period, the system will refill itself up to the Auto Level Probe.

- This process will continue until either the timed cycle end-point or high slurry temperature set-point is reached.

- The auto-fill sequence is disabled and the slurry continues to be heated and mixed until adequate moisture is removed.

- Upon reaching final slurry dryness target, the system is ready to be discharged into a disposal container positioned below the Slurry Dryer tank.

Full Range of Upgrades, Accessories and Services to Unlock Your Evaporator’s Full Potential

ENCON offers a full range of upgrades, accessories and services to minimize labor and maximize return on investment.

Recover your wastewater as clean condensate with our condenser package!

Work with our consultative Sales Engineers to spec a turn-key system.

Utilize our air permitting / permit-exemption services.

Automate with auto-dump or auto-oil-decant.

Free Application Feasibility Report

The centerpiece of our consultative approach is our complimentary bench scale analysis of your waste or process stream. This free analysis determines:

- How appropriate the stream is for evaporation

- Estimated reduction percentage

- Recommended materials of construction

- Recommended operating procedures.

Capacities & Dimensions

Slurry Dryer Specifications

Evaporation Capacity (during evaporation stage): 50 gallons per hour

Dimensions in Inches (L x W x H): 168" x 96" x 244"

Energy Comsumption: 680,000 - 800,000 btu/hr for natural gas/propane heat source. 600-750lbs/hr for steam heat source.

Power Required: 480V/3ph

Model Number Nomenclature

SD-N66-50: First character identifies product as a Slurry Dryer (SD).

SD-N66-50: Second character identifies the heat source for the thermal oil, in this case natural gas (N).

SD-N66-50: Third character identifies the drying tank material of construction, in this case 6% molybdenum super duplex stainless steel (6).

SD-N66-50: Fourth character identifies the mixing paddle material of construction, in this case 6% molybdenum super duplex stainless steel (6).

SD-N66-50: The last character identifies the evaporation rate based on tap water. In this case it is 50 gallons per hour during evaporation mode (50). Note: the rate of evaporation in drying mode will vary based on the properties of the waste stream or sludge.

Why Choose ENCON?

Superior Service & Support – We provide industry-leading technical support, ensuring customers receive prompt and knowledgeable assistance.

Consultative Sales Approach – Our expert sales engineers guide you through the process, including a detailed boil analysis of your waste stream to tailor the perfect evaporator solution.

Proven Industry Experience – With over 2,000 installations worldwide, ENCON evaporators are trusted by some of the largest companies, including 3M, GM, Ford, and Caterpillar, for their reliability and performance.

Wide Range of Heat Source Options – The most extensive selection of heat sources in the industry, ensuring the most cost-effective solution for any application.

Largest Thermal Evaporators in the Market – Designed to handle the most demanding industrial needs, with larger capacities than competitors. Proudly designed and manufactured in the USA.

Unmatched Reliability & Performance – ENCON evaporators are built for longevity, offering superior technical advantages and reliability over competitors.