Zero Liquid Discharge Wastewater Treatment Solutions

- Home

- »

- Products

- »

- Water & Wastewater Treatment Solutions

- »

- Zero Liquid Discharge

What is Zero Liquid Discharge (ZLD) in Wastewater Treatment?

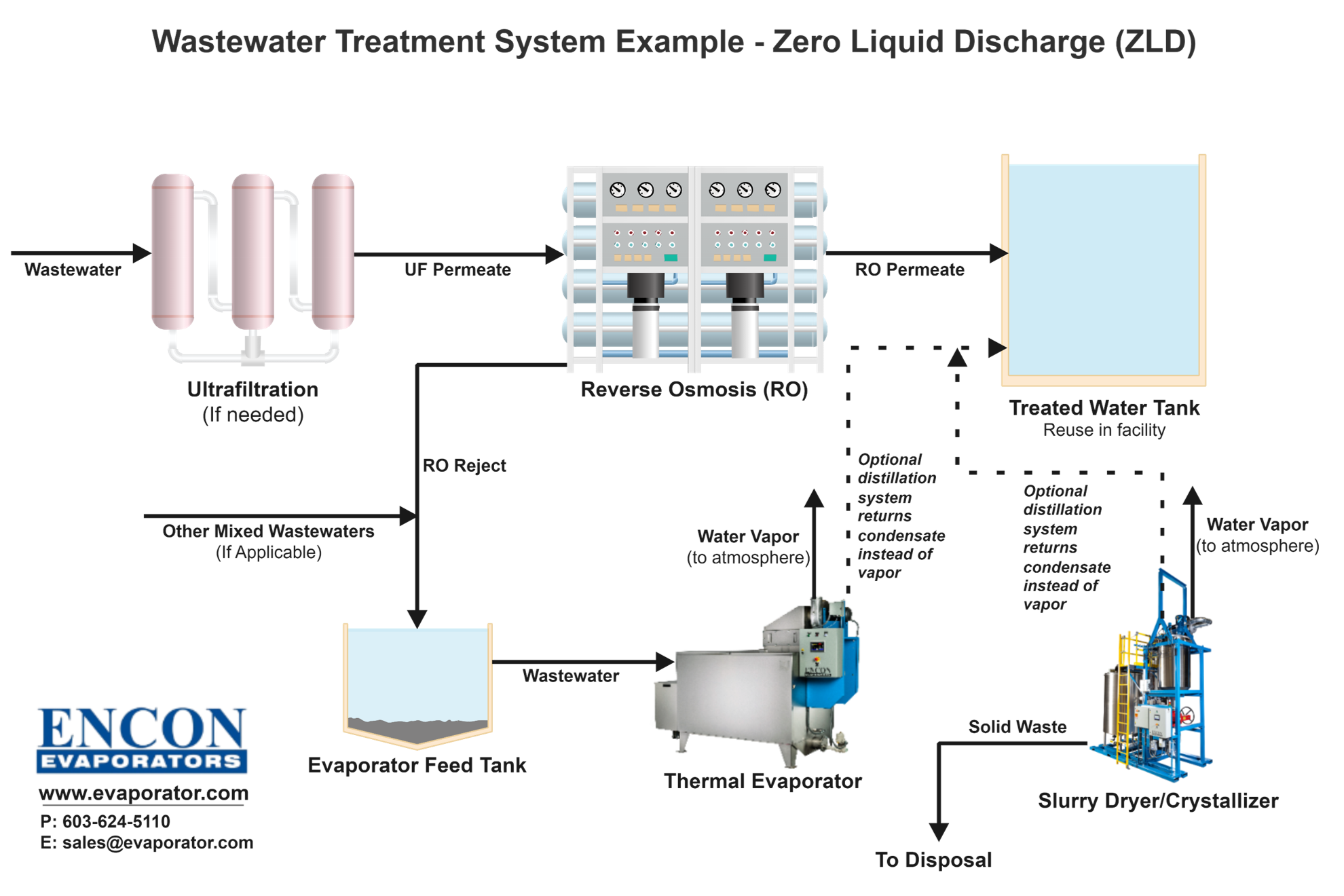

Zero Liquid Discharge (ZLD) is an advanced water/wastewater treatment solution that aims to recover all water used in industrial processes. Water reclamation is maximized and the contaminants are reduced to a solid waste for disposal. This strategy eliminates liquid waste entirely, maximizing water efficiency. ZLD systems typically employ both membrane technologies and thermal processes to achieve zero liquid discharge.

When should my facility implement ZLD?

Zero Liquid Discharge (ZLD) systems are particularly beneficial and make sense to implement in industrial processes under certain circumstances. Following are a few situations where implementing ZLD solutions might be advantageous:

-

When Facing Stringent Regulations: Industries facing strict environmental regulations often find ZLD systems essential for compliance and minimizing liquid waste discharge

-

Cost Control: A properly planned ZLD process should reduce operating costs, not increase them.

-

Water Recovery for Reuse: ZLD solutions are crucial when the goal is to recover all water used in processes, especially in regions where water scarcity is a threat to industry.

-

Environmental Sustainability Goals: Implementing ZLD aligns with corporate sustainability goals by reducing water consumption, minimizing environmental impact, and promoting responsible wastewater management

Defining clear goals and requirements before designing a ZLD system is crucial for its successful implementation and ensuring that it meets the specific needs of the facility.

Typical Industrial Wastewater ZLD Applications:

- Metal working wastewater reclamation

- Cannabis cultivation fertigation wastewater

- Surface finishing wastewater

- Plastics manufacturing wastewater

- Power plant FGD wastewater

- Chemical manufacturing wastewater

- Pharmaceutical wastewater

- Food & Beverage wastewater reuse

- Paper plant effluent