Vacuum Evaporator Process Description

Principles of Operation

The Vacuum Evaporator is a forced circulation flash evaporator utilizing a heat pump circuit for energy recovery resulting in excellent energy efficiency. The heat pump cycle uses electricity to move heat from one place to another instead of generating heat directly. Therefore, the vacuum evaporator is five times more energy efficient than conventional electric resistance evaporators.

KEY DESIGN PRINCIPLES

- Evaporation takes place at low temperature and reduced pressure conditions. The pressure in the separationvessel ranges from 0.7 psia to 1 psia. At this pressure, the boiling point of water is 90-102 °F.

- Energy consumption: 0.57 kWh/gallon of distillate.

- Refrigerant: The ENCON Vacuum Evaporator uses R513a which has a low Global Warming Potential (GWP) of 573 which is lessthan half that of competitors’ systems, is Freon-free, and has an ozone depletion potential of zero.

- Continuous flow system: this means that the solution in the separation vessel is maintained at a constant,maximum desired concentration. Concentrate is continuously discharged and replaced by fresh inlet solution.

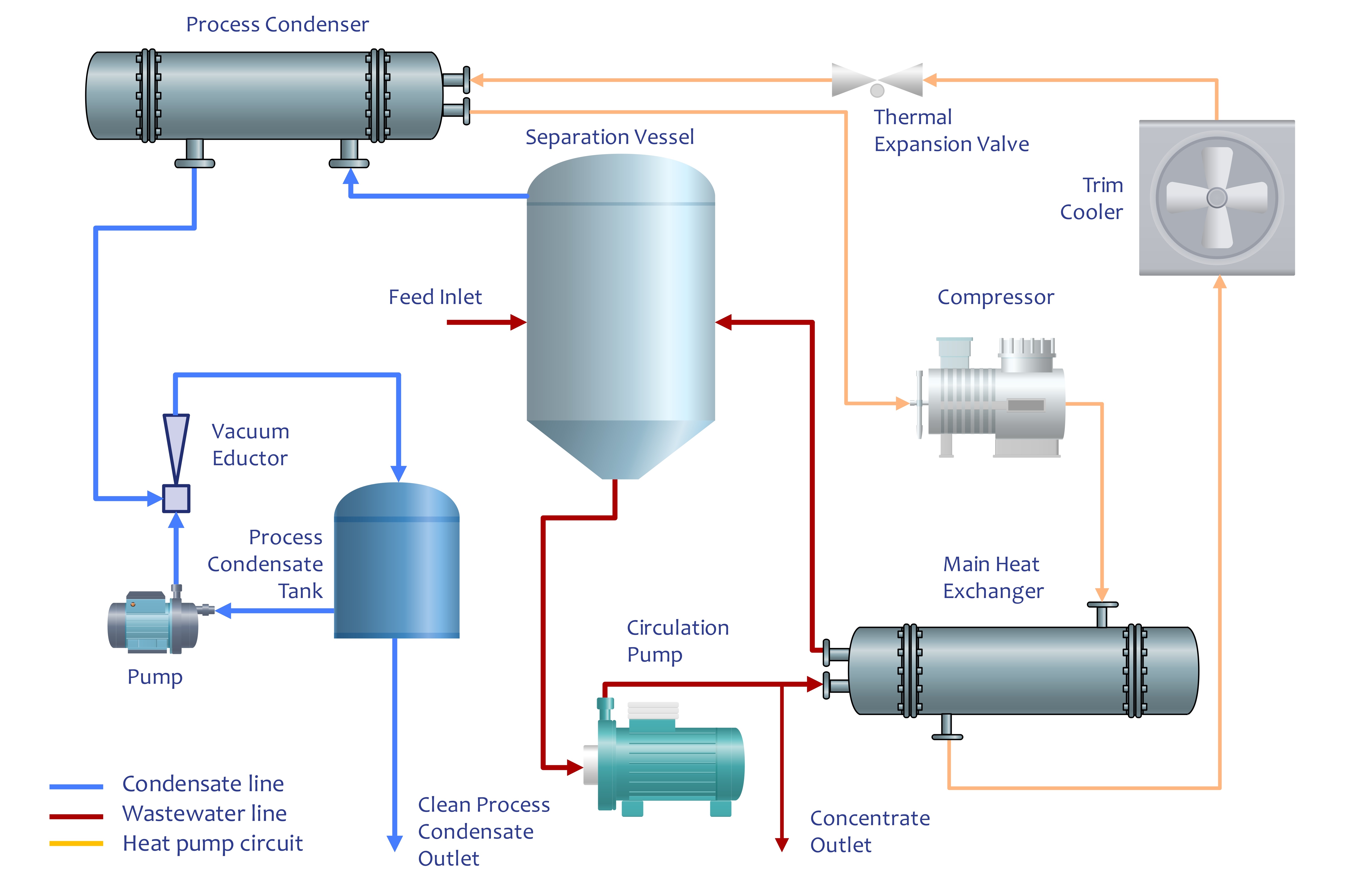

PROCESS DESCRIPTION (refer to diagram below)

FEED WASTEWATER

Wastewater is collected in a holding tank upstream of the evaporator, and fed to the system via the separation vessel.

EVAPORATION

The wastewater is circulated by the circulation pump through the main heat exchanger, where it is heated by hot refrigerant. The heated wastewater is then returned to the separation vessel. Upon arrival, flash evaporation occurs.

CONDENSATION

The water vapor in the vessel exits to the condenser, where It’s condensed by cold refrigerant. Distilled condensate exits the process via the condensate tank.